Industries / Manufacturing

In the manufacturing industry, value added is shifting from assembly to service, and there is a growing trend to secure profits by providing "customer experience" after the sale, rather than "selling out" of hardware and goods.

The concept of "connecting directly with the customer and upgrading the customer experience by updating the software" is being applied to hardware development, and companies are growing rapidly.

High productivity through craftsmanship and on-site improvements, which is the source of value for Japanese companies, is rapidly being overtaken by the progress of digitalization, and at the same time, the room for improvement through digitalization is limited

ExaWizards of point of view

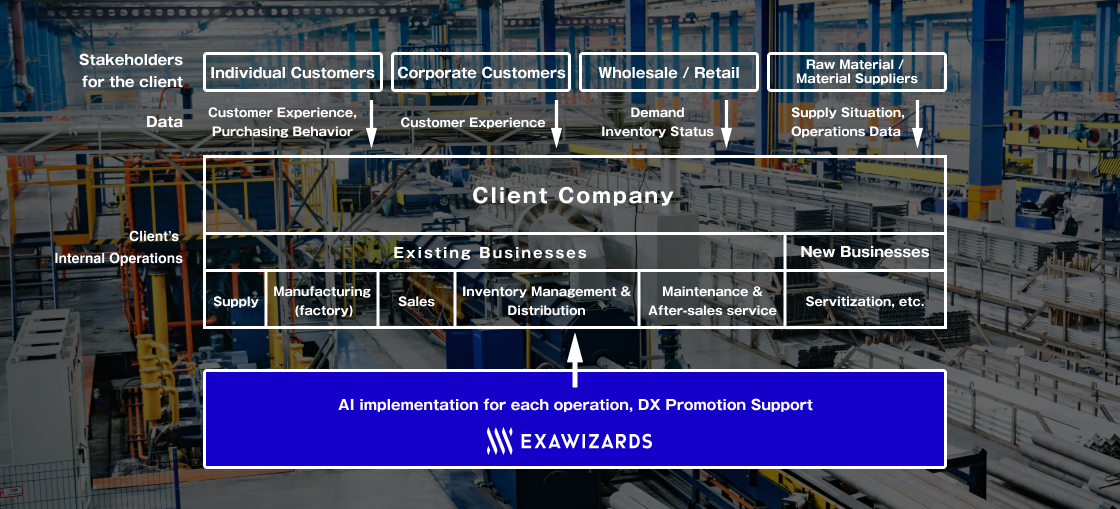

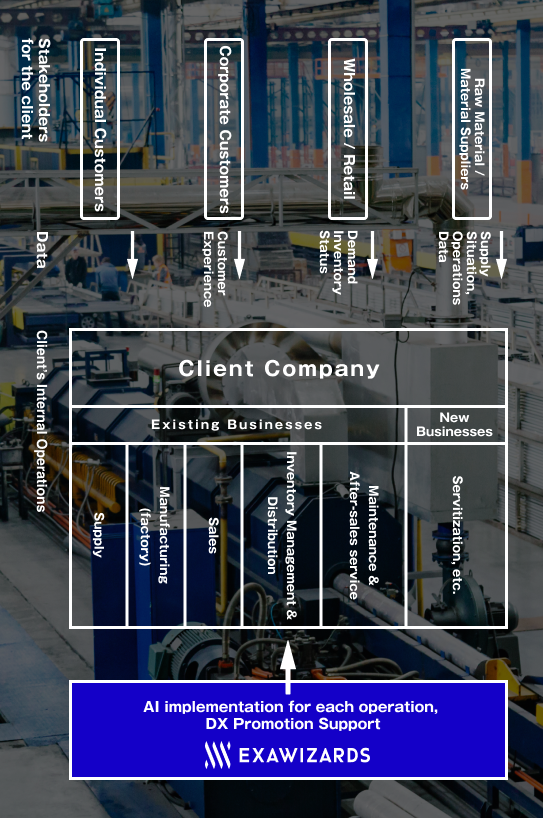

At ExaWizards, we aim to introduce AI with a large impact in the manufacturing industry, which has a long value chain and many opportunities to utilize digital technologies. We will work to implement technology and solve social issues in this industry with three main perspectives:

(1)Improve the productivity of existing businesses by evolving to a data-driven improvement model, where AI analyzes data obtained from digital devices such as sensors and cameras, and experts take action to improve the extracted issues.

(2)Optimize the entire supply chain by integrating procurement and distribution data.

(3)Improving R&D and marketing by directly connecting consumers and manufacturers, visualizing customer experience and behavior data, and incorporating the findings into the engineering chain.

Case study

-

Metal manufacturer design process

With regard to the metal parts prototyping and molding business, the main business has been conducted through special dealers, which has put pressure on profits. In the D2C web service that they were considering, when they receive orders directly from customers, they manually estimated the price over several days, but since the price is unknown at the stage where customers consider placing orders, the UX and order rate have declined.

In response to the above, we have made it possible to use AI to predict the three numerical values required as part of the basis for the estimate: "support volume," "volume to be removed when the product is made," and "plate area," based on the CAD data uploaded by the user, and we expect to be able to generate candidates for the modeling posture using point clouds. -

Chemical manufacturer manufacturing process

In the quality inspection process of chemical products, there is a job that involves repeatedly weighing powders for application to testing machines. This is a semi-regular job that is performed every day, and there is a request to automate the process in order to improve employee productivity. In the weighing process, we aim to achieve the target accuracy by (1) scooping out the powder from the container containing the powder and (2) shaking off the powder scooped out in (1).

ExaWizards first examined the feasibility of using AI to generate the prescribed scooping motion in order to determine the feasibility of (1) from a technological perspective. And we achieved a certain level of accuracy.