Start Providing “exaBase Skill Transfer” to Support Visualization and Transfer of Skills by AI

Realize Visualization of Intuitions and Tips Not Shared in Manufacturing Processes

Provide One-Stop Process from Conceptual Design of Data and Processes to Data Collection, Preprocessing, and Visualization

ExaWizards Inc. (Headquarters: Minato-ku, Tokyo; Representative Director & President: Ko Ishiyama; hereafter, “ExaWizards”) has been solving social issues by services using AI, and has started providing “exaBase Skill Transfer,” which realizes efficient visualization and transfer of skills of skilled workers in manufacturing processes using its multimodal robot AI solution “exaBase Robotics.”

☑︎ What is exaBase Skill Transfer—Realize high-level equalization of processes for which most skills are yet to be shared for transfer in manufacturing processes

ExaWizards has accumulated technology assets provided to over 500 customers through about 250 projects per year in the AI/DX platform “exaBase.” In the multimodal robot solution “exaBase Robotics” in this platform, we started providing “exaBase Skill Transfer” to support visualization and transfer of skills of skilled workers in manufacturing by making use of our knowledge.

This service provides a one-stop process from the conceptual design of data and processes to data collection, preprocessing, and visualization necessary for the final visualization and automation of work done by skilled workers. This enables high-level equalization of processes for which evaluation methods and evaluation indicators have not been shared for transfer.

☑︎Background—Promotion of “remote control/automation” by DX of the industrial base is an urgent issue

The promotion of “remote control/automation” by DX of the industrial base is an urgent issue because of labor shortage and issues of skill transfer in manufacturing sites associated with dwindling birthrate and aging population.

In some business categories of the manufacturing industry, quality assurance in manufacturing processes is maintained by certification of “experts” or “skilled workers,” but recently hiring difficulty due to labor shortage has become visible and the need for replacement of skills by promotion of remote control or drastic “automation” has been increasing.

However, any measures require the introduction of devices in sites and changes in operations, so introduction often takes several years and it is difficult to decide the implementation of the budget due to the difficulty to clarify the cost effectiveness from the viewpoint of management.

For this reason, ExaWizards started providing this service to visualize how much time the current operations require and to what extent skills are shared for the smooth resolution of management issues by operation transformation, preparation of machine guidance, optimization, and automation of control conditions, etc.

[Overview of the service]

(1) Formulation of the concept

Perform conceptual design of data and processes necessary for final visualization and automation.

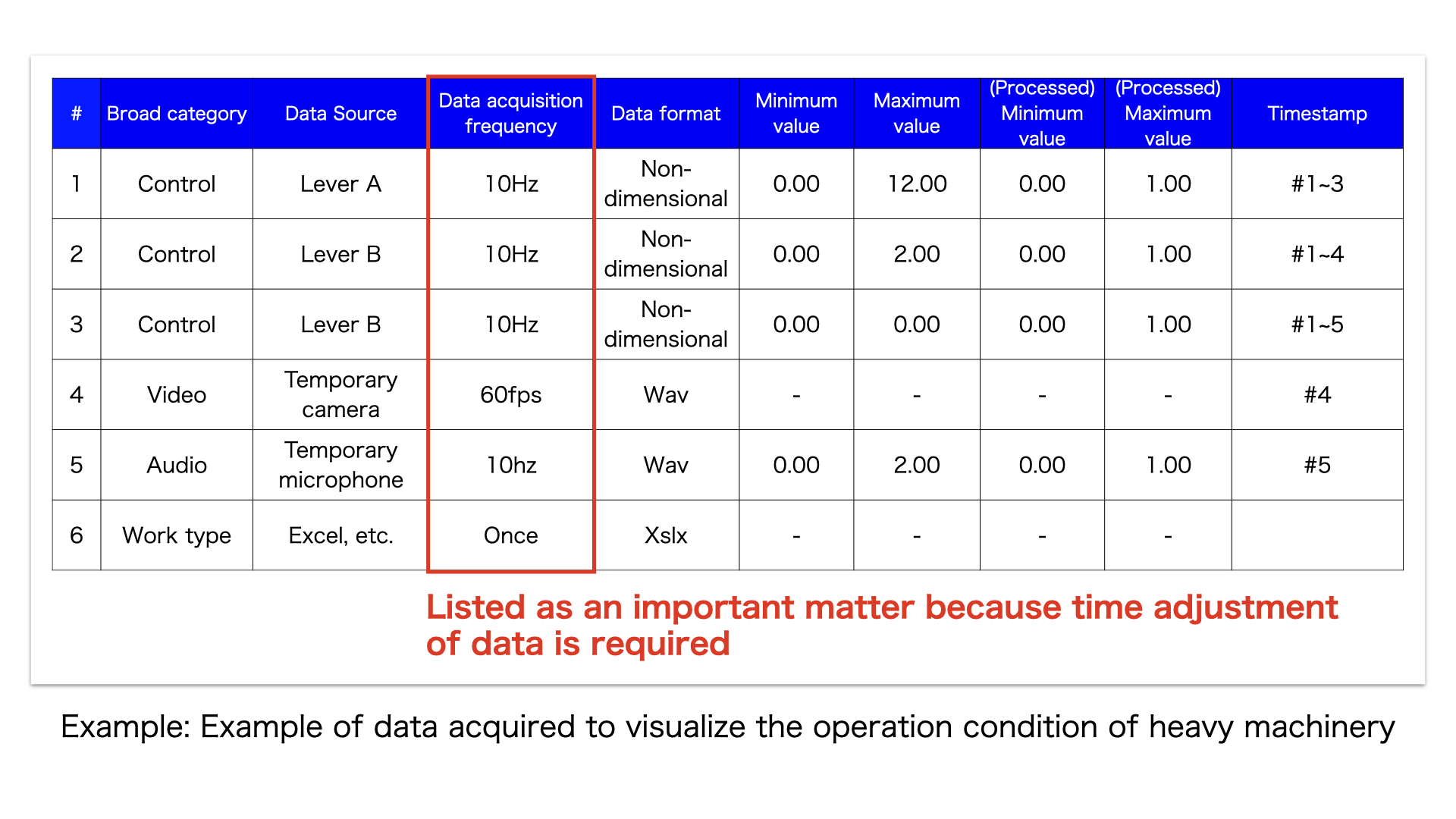

So far, we have found the following issues in aggregation and analysis of the data of sensors for hypothesis in general data analysis projects:

1. Noises may be included

2. Acquired data is biased

3. The data cannot be compared with that of other sensors due to the difference between their acquisition frequencies

4. Preprocessing of data requires such a long schedule/high cost that the process is stopped at PoC

For these issues, the support for the selection of easy-to-use sensors and the data format to be acquired for final analysis are defined from knowledge of robot AI control.

(2) Data collection and preprocessing

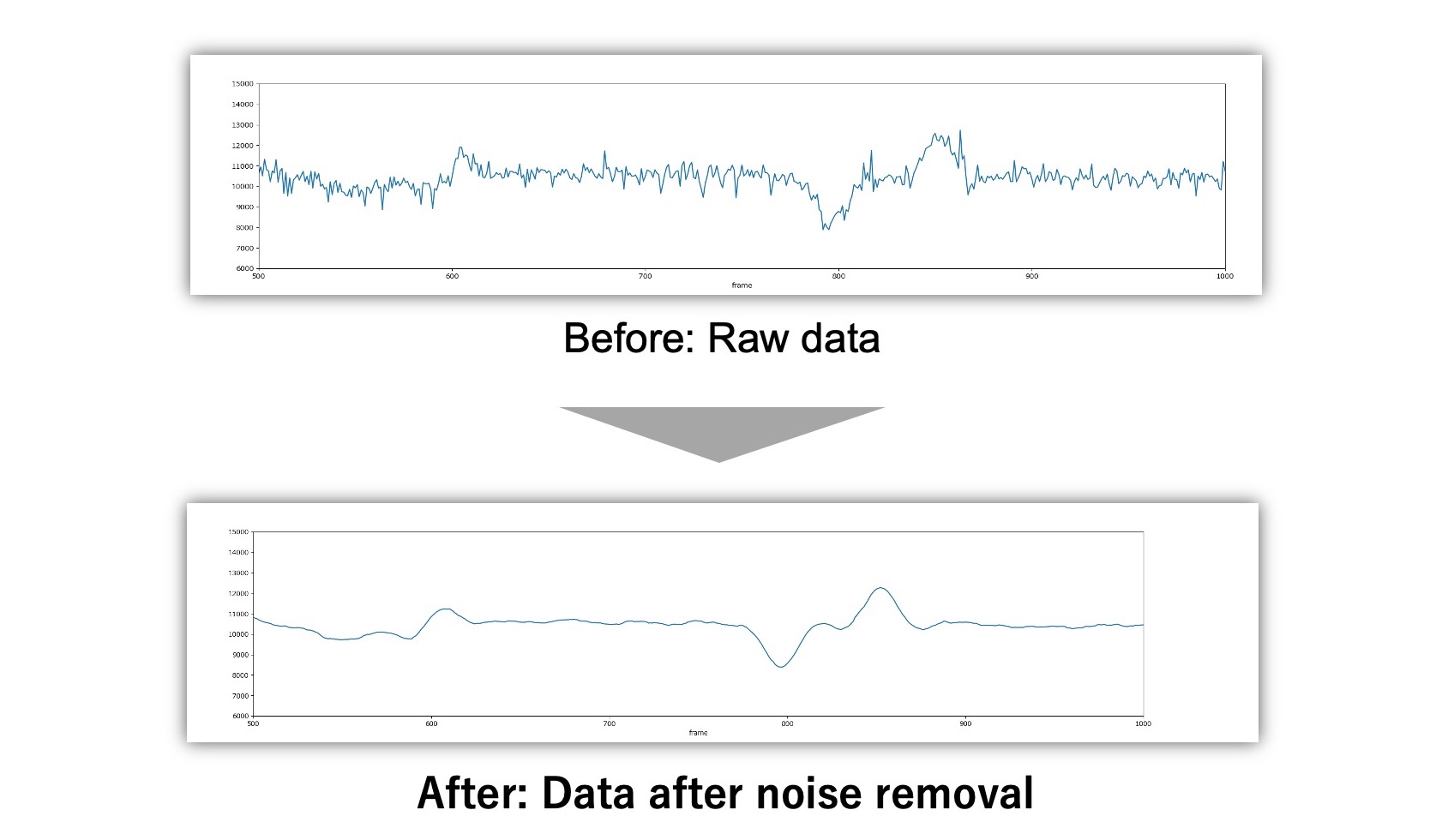

Smoothly execute the preprocessing process in analysis.

Generally, preprocessing processes account for 80% of person-hours in data analysis projects. This service supports the preprocessing process by a selection of the noise removal algorithm, total evaluation of multimodal data, a cutout of work units not clarified, etc. from knowledge of robot AI control in handling multiple systems and time series data.

(3) Visualization of data associated with skills of skilled workers

This service supports the decision of measures from the viewpoint of on-site workers, management and the process in between them by extracting variables with high contribution ratios for objective variables using a large number of algorithms based on the result of preprocessing.

To construct a prediction model by deep learning based on the obtained data in general data analysis projects, the subsequent processes may be difficult to proceed with due to the black-boxing of algorithms in the event of a deviation from the viewpoint of on-site workers.

This service selects algorithms necessary for discussion of the objective and evaluation process and visualizes data associated with the skills of skilled workers (identification of factors with high contribution levels). Then, you can consider measures to be applied to the factors with high contribution levels like automation and adoption of stricter control ranges.

☑︎ Use cases

1. Operation transformation

Elaboration of vague evaluation criteria enables to update work manuals.

Example: Baked conditions have been evaluated by visual inspection in baking lines for cookies, etc. in food factories. However, the evaluation based on colors (RGB, etc.) enables even unskilled workers can evaluate them.

2. Machine guidance

Install guidance software to equalize the intuitions and tips required for the operations of heavy machinery (excavators, cranes, etc.) in the construction and civil engineering industries.

Example: Guide for the elaboration of the timing to raise and lower excavators enables efficient work.

3. Optimization and automation of control conditions

Enable to calculate the optimal equipment control conditions in manufacturing lines considering disturbances (temperature and humidity) and material state (control No.).

*exaBase is a registered trademark of ExaWizards.

【Corporate profile of ExaWizards Inc.】

Company name: ExaWizards Inc.

Head Quarter: 21F, Shiodome Sumitomo Bldg., 1-9-2 Higashi-Shimbashi, Minato-ku, Tokyo

Founded in: February, 2016

Representative: Ko Ishiyama, Representative Director & President

Business Description: Industrial innovation and resolution of social issues through development of AI-based services

Corporate site: https://exawizards.com/