Using the Multimodal Robot AI Solution “exaBase robotics” in Building a Foundation for Efficient Skill Transfer of (Experienced/Senior/Role Model) Workers in Heavy Equipment Operations at Nippon Steel Corporation

Preparing to Install an AI Solution to Improve Efficiency of Slag Separation in East Nippon Works Kimitsu Area

ExaWizards Inc., a company that develops artificial intelligence (AI)-enabled services to solve social issues (hereafter, “ExaWizards“; headquarters: Minato-ku, Tokyo; Representative Director & President: Ko Ishiyama), has built a data analysis platform that enables visualization of work conditions in heavy equipment operations and efficient transfer of (Experienced/Role Model) Workers’s skills through exaBase Robotics, a multimodal robot AI solution provided by ExaWizards.Nippon Steel Corporation (Chiyoda-ku, Tokyo; President: Eiji Hashimoto; hereinafter referred to as “Nippon Steel”) started verifying(Preparing to Install, agreed to start initial testing of) the data analysis platform in the company’s Kimitsu area starting February this year.

☑︎Background

☑︎Background

Against the backdrop of a shortage of manpower due to the declining birthrate and aging population, and the issue of passing on skills at manufacturing sites,

the promotion of “remoteization and automation” through DX of industrial infrastructure has become an urgent issue.

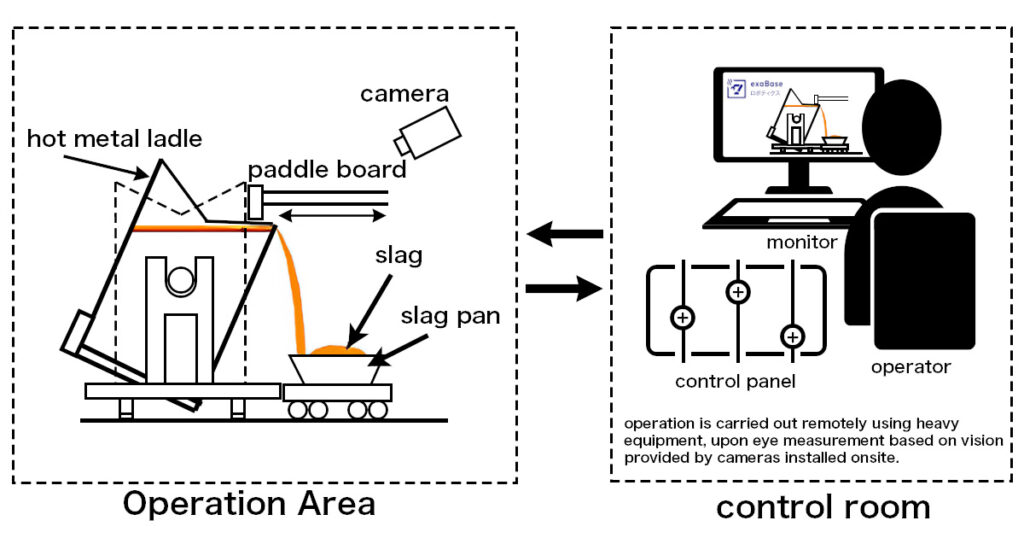

At steel mills, it is necessary to separate the slag* that is generated at smelting & refining of molten iron.

Since this work involves handling molten material at temperatures of over 1,000 degrees Celsius,

the workers use heavy machinery to remotely operate the equipment while checking with cameras installed at the site.

It is important to make decisions based on the knowledge and experience of the workers in order to work in changing conditions of hot metal, and it has been difficult to index the actual work and formalize the skills and know-how of the skilled workers in order to promote efficient skills transfer.

*Slag is a by-product of metal smelting & refining.

☑︎AI presents key points of slag separation for operator by visualizing data to improve efficiency and raising the benchmark of operations

To solve the above issues, ExaWizards and Nippon Steel have been working on a project to digitize heavy equipment operations in slag separation. As a part of this project, a data analysis platform has been built using “exaBase Robotics” to enable skill transition between workers in heavy machinery operations, and on-site testing has begun in East Nippon Works Kimitsu Area.

There are 2 key values delivered through this platform; the visualization of data never digitized previously in heavy equipment operations, and the analysis of operating skills to clarify key expertise shared in senior operators with more than 10 years of experience in the field . This expertise data will be used to assist new operators by aiding them through key operational actions, so that they can perform the same operations as experienced operators.

Figure 1: Image of slag separation work in the steelmaking process

Figure 1: Image of slag separation work in the steelmaking process

[Data Analysis Overview]

(1) Sensor data: Operating position, speed, etc. of heavy equipment

Sensors collect control board operation data and the real-time head position of machinery to acquire operator’s operation controls and positional fluctuations, used as input to analyze operation traits.

(2) Video data: Slag separation operation status, molten material status, etc

Software analyzes slag separation status from image data obtained from cameras mounted in the operation area.

(3) Operation records: date, time, and staff information of operation

Software integrates worker data, date/time of operation, and difficulty of operation to analyze

characteristics of each person

*Image is for reference only.

*Image is for reference only.

[About exaBase Robotics]

Site:https://exawizards.com/exabase/robotics/

Site:https://exawizards.com/exabase/robotics/

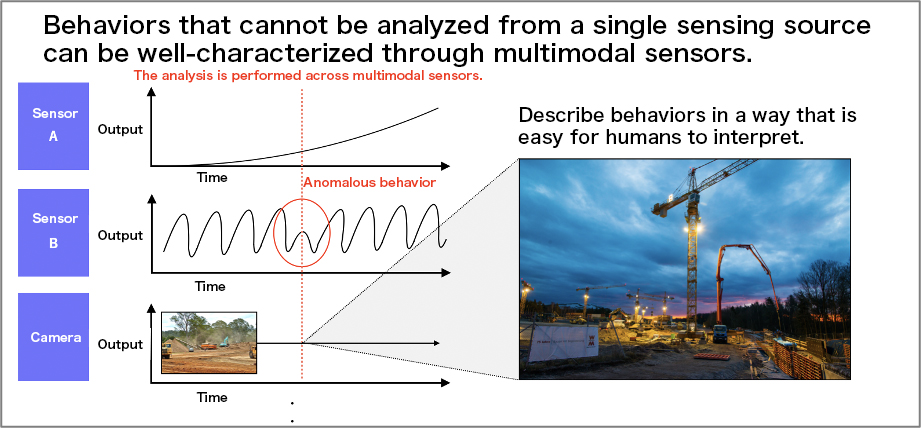

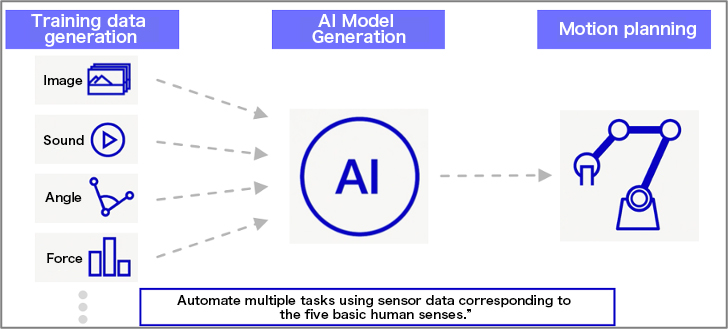

exaBase Robotics is a part of the AI platform “exaBase”. exaBase Robotics can characterize and streamline various operations by utilizing a wide range of multimodal data such as image data and time series sensor data, which can be either real or synthetic data. exaBase Robotics is used in a variety of scenes; from automating simple tasks, to characterizing and transferring advanced skills.

[Examples of use case]

1. Grasping of organic shaped objects

Capable of grasping food with organic shapes such as vegetables, fish, etc., and reflective/transparent objects.

2. Powder Weighing

Highly accurate measurement of a wide variety of powders

3. Characterize and transfer advanced skills

Characterize and transfer advanced skills in operations such as grinding, polishing, heavy equipment operation, and automation with robots

☑︎Exhibition of “exaBase Robotics” at iREX2022 (International Robot Exhibition 2022)

ExaWizards helps customers characterize and streamline highly skilled operations in a variety of industries. A notable project reference is our showcased in our release with Nippon Steel Corporation in “Transferring Advanced Skills,” one of the use cases exaBase Robotics supports.

At the 2022 International Robot Exhibition, to be held at Tokyo Big Sight from March 9 (Wed.) to 12 (Sat.), 2022, ExaWizards will exhibit an AI robot system that reproduces a top chef’s serving skills by learning the tacit knowledge of food presentation as a model use case in the food industry.

*exaBase is a registered trademark of ExaWizards.

[ExaWizards Corporate Profile]

Company name: ExaWizards Inc.

Head Quarter: 21F, Shiodome Sumitomo Bldg., 1-9-2 Higashi-Shimbashi, Minato-ku, Tokyo

Founded in: February, 2016

Representative: Ko Ishiyama, Representative Director & President

Business Description: Industrial innovation and resolution of social issues through development of AI-based services

Corporate site: https://exawizards.com/

<Inquiries about PR>

Public Relations Department, ExaWizards Inc.

E-mail: publicrelations@exwzd.com